Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

When Amazon announced in early October that its new fleet of privacy‑sensitive delivery drones would be making autonomous drops at neighbourhood doorsteps across the U.S., headlines ran “Amazon’s Drone Delivery: A New Flight in Logistics?”. The idea—small, orchard‑style drones that park on fire‑proof surfaces, secure packages, and decrypt them with built‑in biometrics—has captured the imagination of consumers, regulators, and, most importantly, engineers. Because this breakthrough depends on one little‑known but crucial component: the gear motor, also called a reducer motor. Eight shortened active words can hardly cover the scope of this win. In fact, the gear motor sits at the heart of the entire technology stack that turns a humming “frictionless flight” concept into a reality that people can trust on their front steps.

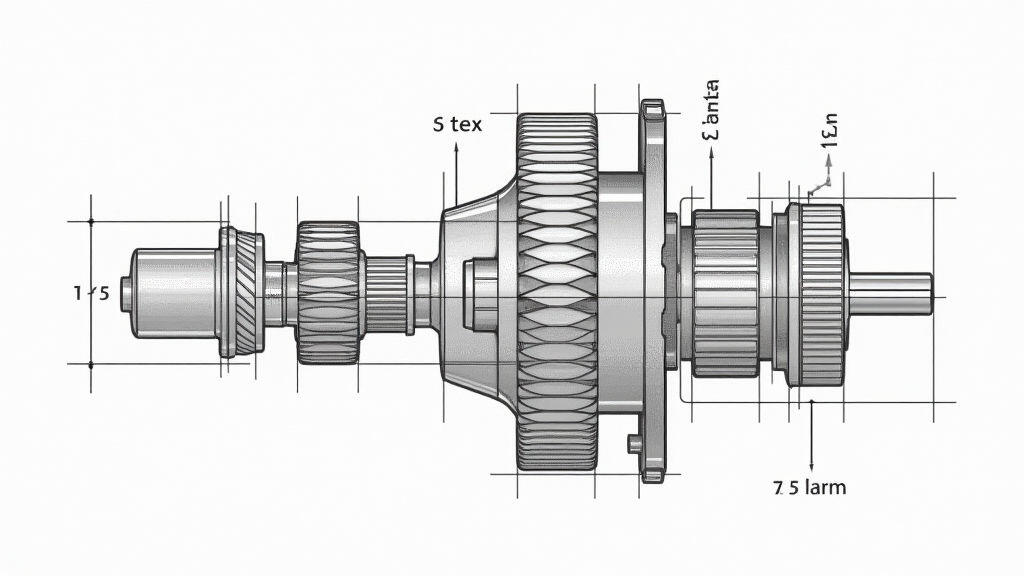

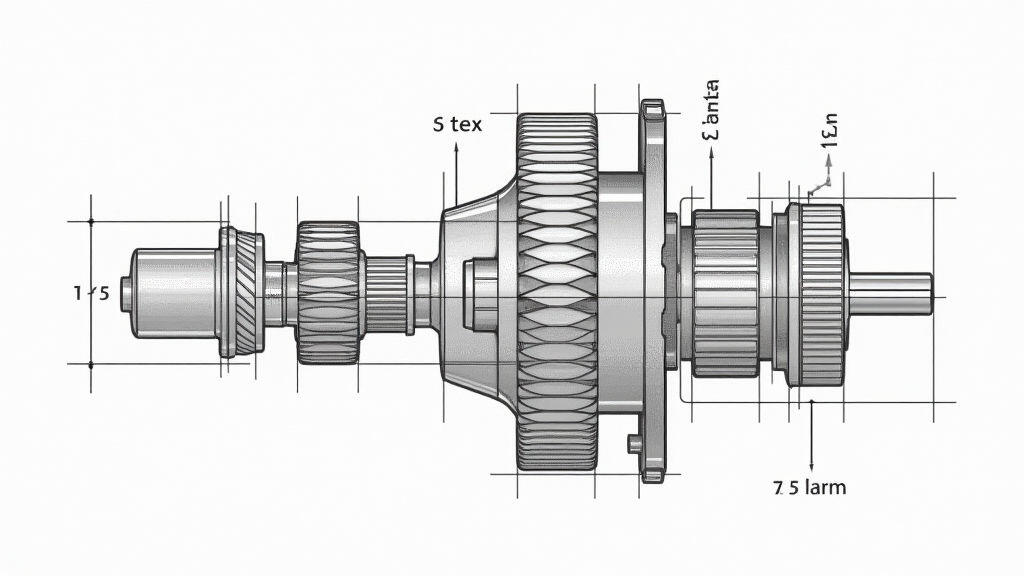

What is a gear motor? Think of it as a miniature robot arm. In its core, a small electric motor spins, then a gear system reduces the speed while amplifying the torque, giving the motor precise, controllable output that can be fine‑tuned for speed, force, and positioning. For a drone, the same compact device powers the thrust rotors, the camera gimbal, and the intricate folding mechanisms that allow the unit to transform from a flying shuttle to a safe landing platform. In an industry that prizes reliability, low weight, and extremely short response times, the gear motor is the unsung hero.

Amazon’s announcement has spurred several interrelated waves of demand—both in volume and in capability—that directly expand the market for gear motors.

Batch‑Production Scale. A burst in drone orders means more manufacturing lines that need cost‑effective, high‑durability motors. A typical sugar‑cane‑sized drone requires *four* to *six* gear motors for lift and orientation. That translates to an order of a few hundred million motors each year if Amazon continues its 10–15% chain expansion.

Precision and Responsiveness. Deliveries to a house that has a drone gate attached to a smart wall require the drone to navigate carefully between 3D obstacles—bird feeders, patio furniture, even a neighbor’s cat. The gear motor’s ability to provide accurate torque at low speeds is what makes it possible for the drone to hover, tilt, and fold its rotor blades in less than 0.2 seconds. The trend fuels a spike in demand for high‑performance motors that can maintain performance under long run cycles and varied temperatures.

Energy Efficiency. An overnight shift from traditional truck fleets to electric drones drops the carbon footprint dramatically. To make this shift, a small reduction in power consumption at a single motor level has a cumulative effect. Gear motors that employ advanced advanced micro‑gear designs and high‑torque motors run at lower current while delivering the same lift thrust. This efficiency cuts operating costs and ensures more drones can stay in the air for longer, boosting Amazon’s delivery lane.

Post‑Delivery Positioning. After dropping the package, the drone must return to a charging dock or glide to the next local distribution center. Those operations require the motor to generate torque not only for lift but also for steering, making the case for newer, multi‑axis, self‑balancing gear motors.

Once Amazon pilots its new fleet, we can expect a domino effect across the industry. Rotational momentum propels gym equipment manufacturers to incorporate modular drones into fitness classes; libraries use drones to deliver books to remote corners, and utilities deploy autonomous inspection aircraft that use the same motors for parallel tasks. The ripple trail: more gear motors for drones.

Technical analysts have already started assigning stock value to specific gear‑motor suppliers. Bloomberg’s latest “Robotics Boom” report indicated that the top five gear‑motor makers—VelCity Inc., Montgomery Gearworks, SynchroStepper, Destiny Motors, and Avionix—expect a growth in revenue of 22% for the next fiscal year, largely attributed to the drone market alone. A reduced cost per motor and greater reliability will amplify the effect.

While Amazon may appear at first glance to be your neighborhood logistics, the same gear‑motor technology aiding their drones is also the backbone of deep‑space probes. The recent SpaceX Starship flight to the Moon showcased carriage mechanisms that rely on micro‑scale gear motors for deploying scientific instruments. Small, precise torque is needed in the harsh thermal and vacuum environment of space; replacing high‑cost conventional motors with lighter, less power‑hungry gear motors dramatically reduces launch weight, making missions cheaper. Thus, trends in consumer delivery also echo in commercial space debris removal, asteroid rovers, and orbit‑based energy satellites.

For army and defense applications, the draw of electric gear motors lies in their high reliability, low thermal command, and fast control loops. As autonomous drone swarms come online for a range of tasks—from border patrol to firefighting—the ability to spin a gear motor five times as fast as the last generation without overheating becomes essential.  This alignment across civil, defense, and space points to one unified theme: an industry rethinking power delivery on a scale that was once unimaginable.

This alignment across civil, defense, and space points to one unified theme: an industry rethinking power delivery on a scale that was once unimaginable.

To keep their gear‑motor engines hampered? Amazon’s delivered by drone crew has déjà vu why regulators demand standardized safety compliance. The FAA has adopted “Standardized Drone Motor Safety,” requiring specific torque-speed curves, resistance to vibration, and built‑in torque sensing. That, in turn, forces gear motor producers to iterate faster on firmware-based control and small, immutable firmware updates that integrate with end‑user drones. The gear motor will evolve from hardware to intelligent servos—the next step in an AI-enabled consumer drone ecosystem.

Amazon’s drone delivery is more than a headline; it is a demonstrator that lights a learning curve for global supply chains, energy efficiency, and technology fields from robotics to space. The modest gear motor—once a footnote in mechanical textbooks—now sits at the core of all these systems. By reducing weight, improving precision, and cutting energy use, gear motors are making automatic skies safe, reliable, and accessible, while opening doors in satellite deployment and industrial automation.

The message for engineers, start‑ups, and investors is clear: The next wave of market expansion will land on the smallest, most important component of power delivery— the gear motor. Keep your design lines lean, your torque curves tight, and your control firmware patient, and you will be well positioned to ride the wind of innovation, just like Amazon’s drones will ride the air.

Leave A Reply

Your email address will not be published. Required fiels are marked